SpinnyBoi3002

It’s time for the 3rd iteration of SpinnyBoi; this one too, will spin. Perhaps even spin better?

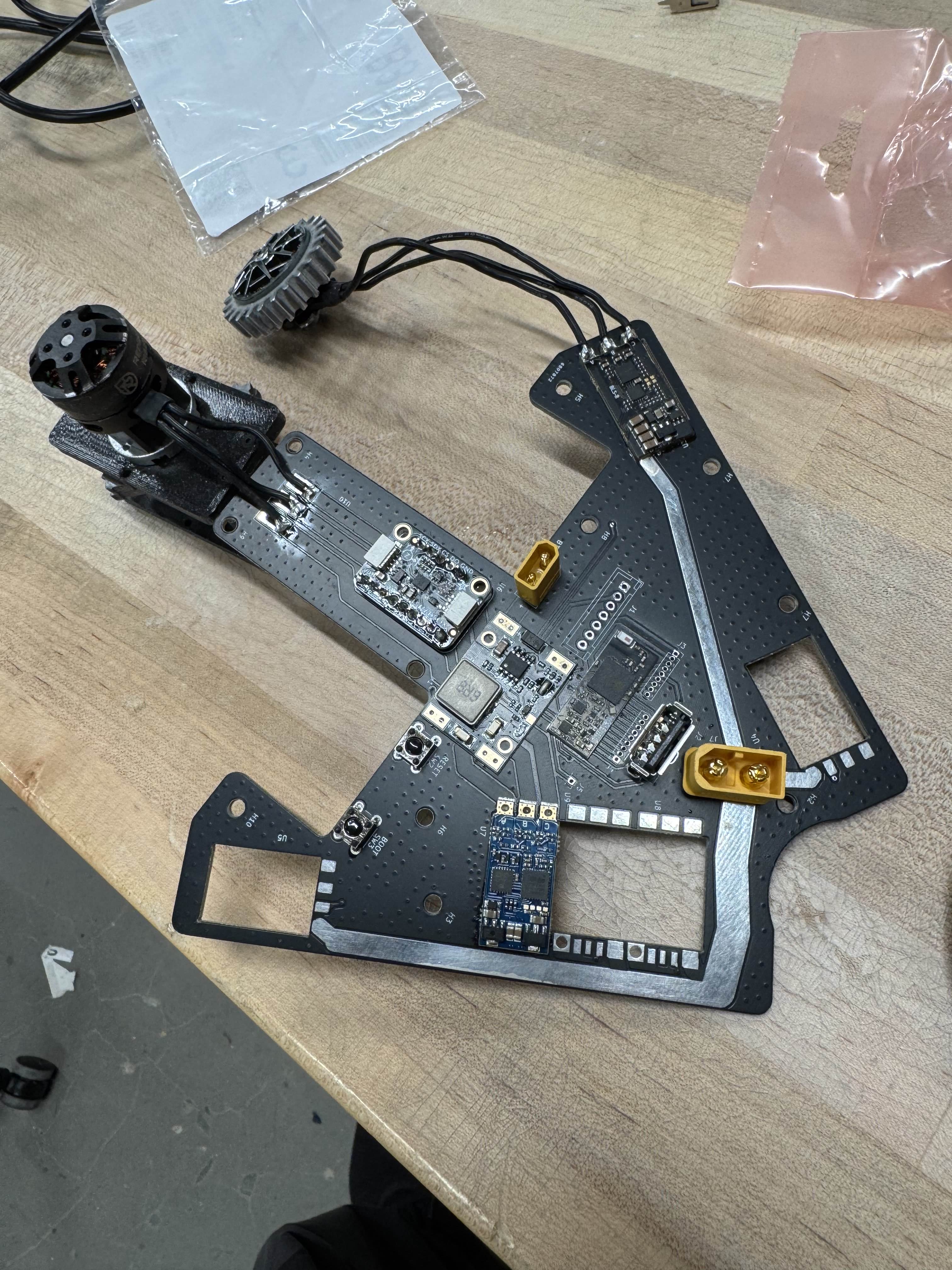

The fundemental premise is the same: a ring spinner that can move omnidirectionally. Structurally and electrically however, a lot has changed.

3001 was constructed with the two halves of the outer ring split on the z plane, and bolted together with a ring of 12 m3 bolts. I had forseen there to be lateral load, and as such added m5 dowels to both absorb blade impact and to share radial load from one half to another. I figured that there would be any axial load because the two rings were coradial, and thus difficult to hit one half without hitting the other. What I did not account for was that the blade tip sandwhiched between the two halves would act as a prybar and that any vertical load on the blade tip would tranfer to the ring halves. Long story short, that’s exactly what happened, and the ring split completely in half during our final fight.

INSERT IMAGE HERE

Because of this weakness, I decided to move the split from the z plane to the y plane, creating two semicircles. Now, the blade tips would also function structurally to hold the two halves together. This works out nicely because the (thinner) middle part, which needs to be very strong because it’s an impactor, also can lend it’s strength to the structure of the ring. FEA (to the best of my ability) shows that it loads quite well. The blade tips are S7 tool steel for it’s incredible tensile and impact strength (but also because that’s what I have avalible to me), while the halves are 5052 (also because of it’s avalibility).

INSERT IMAGE HERE

For the past 2 iterations, the bearings the ring ride on were parallel to the z plane. While this seems to have worked alright, it’s non-optimal because 1. it requires two reference faces to constrain axially and radially (which is a little annoying to make), 2. vertical load results in axial load for the bearings, and ball bearings don’t particularly like axial loading. Thus, I switched to an angled contact surface, which should at least reduce both of these problems. While it poses a more annoying machining problem, it should be a net benefit.

INSERT IMAGE HERE